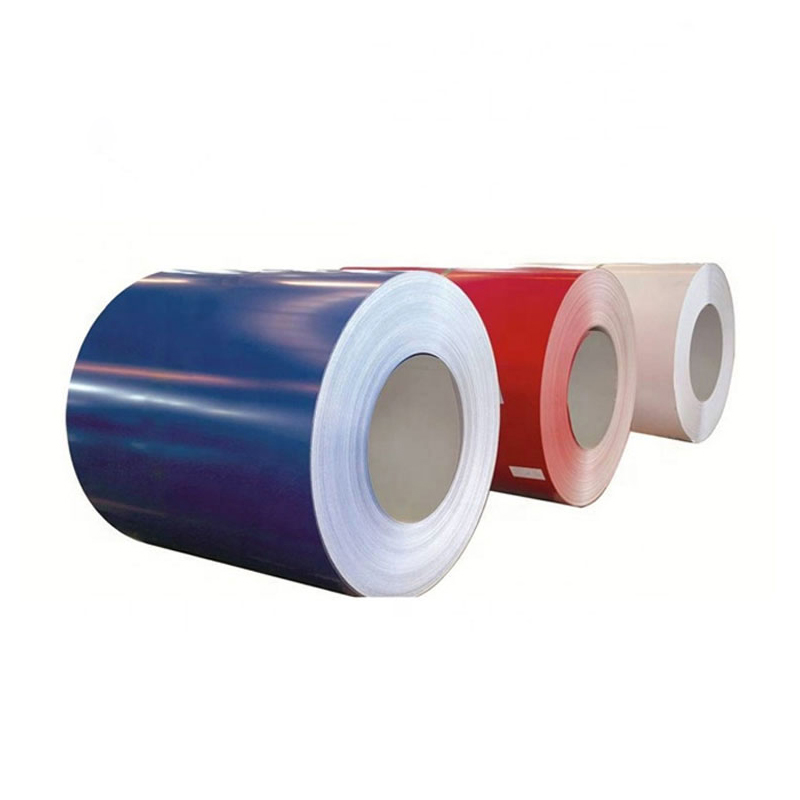

Product name:Pre-Painted Galvanized Coil (PPGI)

Also known as coated rolled steel coils and color coated steel coils, PPGI are a flat steel product on which protective decorative paint is applied. A polymer coating is available in various colours as well as a matte, lustre or decorative natural finish (granite, wood, etc). Organic coated galvanized steel is corrosion-resistant, has excellent mechanical properties and can be formed, profiled or stamped.

| Product Name | Pre-Painted Galvanized Coil (PPGI) |

| Standard | ASTM,DIN,JIS,BS,GB/T, etc. |

| Material | Dx51D,Dx52D,Dx53D,Dx54D,S250GD,S350GD,S550GD |

| Zinc coating | 30-275g/m2 |

| width | 900mm-1000mmor as required |

| thickness | 0.2mm-15mm or as required |

| Coil Weight | 3-8 Tons, or as required |

| Color | Standard Color: red, blue, White, Gray Special Colors: based on Ral colors |

| Application | House, bridge, transmission tower, ship, industrial furnace |

| MOQ | 3 Tons, more quantity price will be lower |

| Price | negotiable |

| Payment Terms | L/C, T/T, etc. |

| Supply Ability | 10000 Ton/Tons per Month |

| Delivery Time | 7-15 Days |

| Packing | Standard sea-worthy packing, or according to customer required |

The pre-painted galvanized coils are a product obtained by subjecting a hot-dipped galvanized steel sheet to a surface chemical treatment, applying organic coating on the surface, followed by baking and curing.

There are many advantages of PPGI.

Corrosion Resistance: PPGI coils are galvanized with a zinc coating, providing excellent protection against corrosion. This makes them suitable for outdoor applications and areas with high humidity or exposure to harsh elements.

Durability: The zinc coating on PPGI coils enhances their durability, making them resistant to scratches, abrasion, and weathering. This ensures they can withstand long-term use without significant degradation.

Easy Maintenance: PPGI coils require minimal maintenance due to their excellent corrosion resistance and durable finish. Regular cleaning with mild detergents is usually sufficient to keep them in good condition.

Environmental Friendly: PPGI coils are manufactured using eco-friendly processes and materials. The zinc coating provides a barrier against rust, reducing the need for frequent repainting or replacement, thus minimizing waste generation.

Application areas

In the construction industry: to manufacture exterior and Interior products such as metal shingles, corrugated sheeting, sandwich panels, profiles, metallic ceilings, skirting boards, decorative panels inside heated and non- heated rooms, elevators, doors window shutters, shelves etc.

In the automotive industry: to manufacture external and internal car body parts (car doors, car boots, oil filters, dashboards, windscreen wipers etc.)

In manufacture of home appliances, furniture, and consumer goods: metallic furniture, lighting equipment, shelves, radiators, сar doors, car boots etc.